Hopper Bottom Silos Manufacturers

Prairies Partners Global Solution stands out as one of the most trusted and leading manufacturers and suppliers of hopper bottom silos Manufacturers in India. With a strong reputation for delivering durable and high-performance grain storage solutions, we cater to a wide range of agricultural and industrial needs across the country.

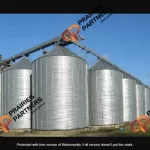

Our hopper bottom silos are specifically engineered for the safe and efficient storage of bulk grains such as wheat, rice, corn, barley, and other cereals. These silos feature a uniquely designed sloped or conical bottom, which allows for smooth, consistent discharge of grain without manual intervention. This innovative design not only minimizes grain residue but also significantly enhances handling efficiency and reduces labor costs.

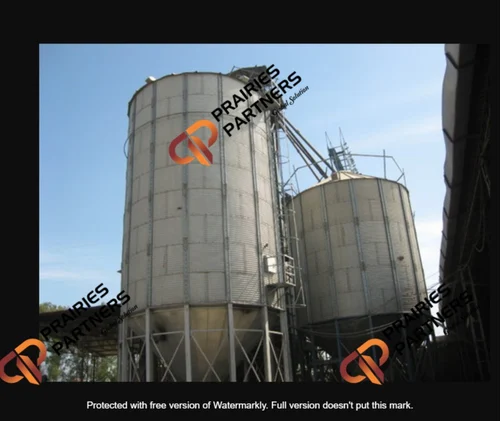

At Prairies Partners Global Solution, we prioritize quality, durability, and precision in every product we manufacture. Our silos are constructed using high-grade steel components. The conical bottoms are made from heavy-duty steel plates, while the cylindrical walls consist of corrugated galvanized sheets, assembled with high-strength bolts and waterproof washers. Vertical stiffeners and circular purlins provide additional structural stability. A sloped roof crowns the top, ensuring optimal weather protection.

We take pride in being one of the best hopper bottom silo manufacturers and suppliers in India, offering customizable solutions tailored to meet your grain storage capacity and site-specific requirements. Whether you’re a small-scale farmer or a large agribusiness, our silos are built to deliver unmatched performance, longevity, and safety.

Key Features of Hopper Bottom Silos by Prairies Partners Global Pvt. Ltd.

1. Robust Galvanized Steel Construction – At the core of every silo is its structural integrity. Prairies Partners uses high-tensile galvanized steel (minimum Z275 coating or higher) to ensure maximum corrosion resistance, strength, and longevity. The galvanized panels are precision-formed with interlocking joints and stiffeners that enhance load-bearing capacity even in demanding environments.

2. Modular and Scalable Design – Prairies Partners designs its hopper bottom silos in a modular configuration, allowing for customized capacity ranging from 5 MT to 1500 MT or more. The modularity ensures that the silos can be scaled up or adapted to various industry needs—be it farms, food processors, feed mills, or grain terminals.

3. Perfectly Engineered Hopper Angle – The company offers silos with hopper angles ranging from 45° to 60°, depending on the type of grain or material stored. A steep hopper angle ensures smooth, clog-free flow, minimizing residue and material build-up. These angles are designed based on flow characteristics and density of the stored commodity.

4. Heavy-Duty Support Structure – The hopper cone is supported by structurally sound steel legs and a frame, engineered to withstand dynamic and static loads. The support systems undergo rigorous testing and analysis using finite element software to ensure safety under all load conditions, including seismic and wind loads.

5. Weatherproof Roof and Ventilation – The roof of the hopper bottom silo is crafted with reinforced panels and equipped with ventilators, manholes, and inspection hatches. Proper ventilation prevents moisture accumulation, mold growth, and temperature rise, ensuring grain quality is preserved over time.

6. Aeration and Temperature Monitoring System – To maintain the quality of stored grain, aeration systems with strategically placed air ducts are integrated into the silo floor. Additionally, temperature monitoring cables are embedded to track heat levels and detect any early signs of spoilage or insect activity.

7. Efficient Discharge Mechanism – Thanks to the conical hopper base, the discharge is gravity-fed and obstruction-free. Depending on user requirements, silos can be fitted with manual, semi-automatic, or fully automatic discharge gates. For high-capacity needs, screw conveyors or pneumatic systems can be integrated.

8. Ease of Maintenance and Inspection – Maintenance is simplified with accessible external ladders, safety cages, internal ladders, and inspection hatches. Operators can inspect grain levels, clean the interior, or perform minor repairs without dismantling the structure.

9. Quick Installation with Bolted Assembly – Prairies Partners uses a bolted panel assembly system, allowing for quick on-site installation without welding. This not only speeds up deployment but also ensures high dimensional accuracy and uniform structural load distribution.

10. Compliance with Global Quality Standards – Each silo is manufactured in compliance with international silo design standards such as IS 9178, ANSI, DIN, and Eurocode. Quality control measures are enforced throughout production, from material procurement to final assembly.

Our Products

Prairies Partners Global Solution is your trusted partner for high-quality, durable, and efficient hopper bottom silos in India. Our silos are engineered to meet the highest standards of grain storage, ensuring smooth unloading, structural strength, and long-term performance. With customizable designs, superior materials, and expert craftsmanship, we deliver solutions that add real value to your agricultural or industrial operations.

Whether you’re looking to improve grain handling efficiency, reduce manual labor, or expand your storage capacity, our hopper bottom silos are the ideal choice. Contact us today to discuss your storage needs and let our team provide you with the best solution tailored to your requirements.

Choose excellence. Choose reliability. Choose Prairies Partners Global Solution – India’s leading hopper bottom silo manufacturer and supplier.